DIN 1.2311 PLASTIC MOULD STEEL

| STANDARDS | 40CrMnNiMo7 | P20 | DIN 2311 | AISI P20 | AFNOR Z210CW12-01 |

DIN 1.2311 Plastic Mould Steel CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Mo |

| 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.030max | 0.030max | 1.80-2.10 | 0.15-0.35 |

DIN 1.2311 steel is the pre hardened plastic mould steel and the hardness is distributed uniformly in large cross sections that have fantastic weldability with minimum hardness, high polish ability and less streak texture making finishing easier.

STEEL PROPERTIES

- DIN 1.2311 steel is pre-hardened plastic mould steel

- Hardness is distributed uniformly in large cross sections

- Fantastic weldability

- Size Section accessibility up to 255 mm thickness

- Supply hardness is 240-280 BHN

- Least hardness elevation

- Good mirror polish ability

- Less streak texture making finishing easier

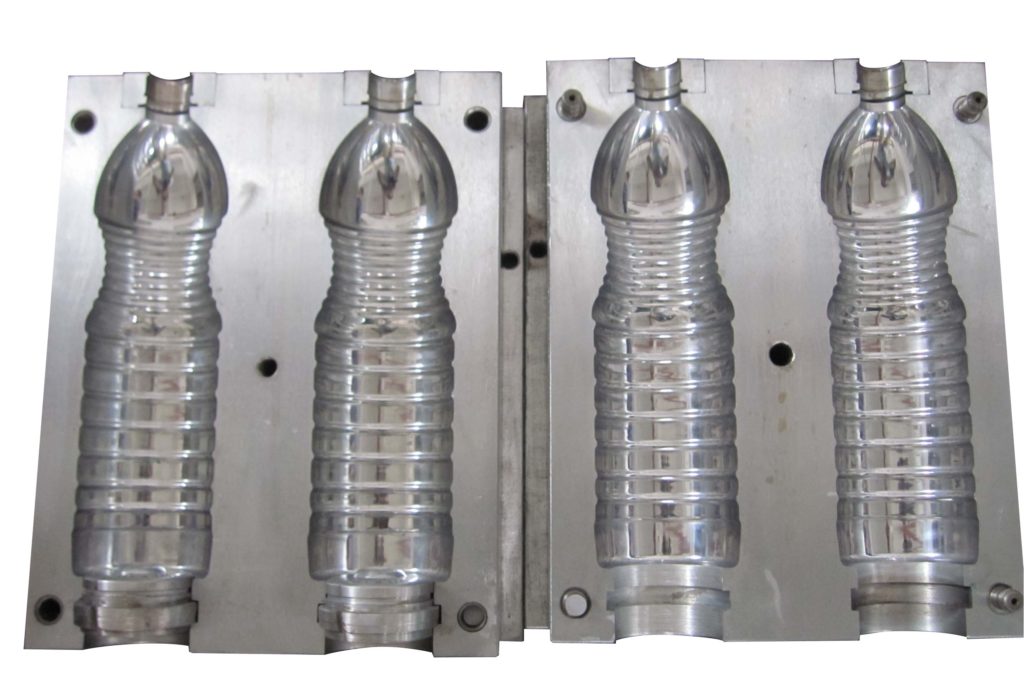

APPLICATION

The DIN 2311 steel is an equivalent to P20 plastic mould steel and used for die holders, casting dies, zinc die, bolsters, backers, shoe blocks, injection moulds, mould frames for plastic moulds, pressure casting moulds, recipient sleeves etc.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 12.7 |

| 20-150 | 12.8 |

| 20-200 | 13.1 |

| 20-250 | 13.3 |

| 20-300 | 13.6 |

| 20-350 | 13.7 |

| 20-400 | 13.8 |

| 20-450 | 14 |

| 20-500 | 14.3 |

| Thermal Conductivity at °C | W / (m*K) |

| 23 | 32 |

| 150 | 32.8 |

| 300 | 31.4 |

| 350 | 30.2 |

| 400 | 29.6 |

| 500 | 27.5 |

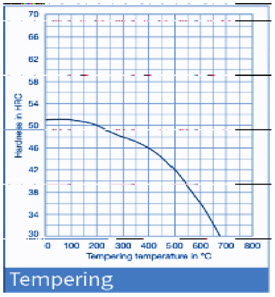

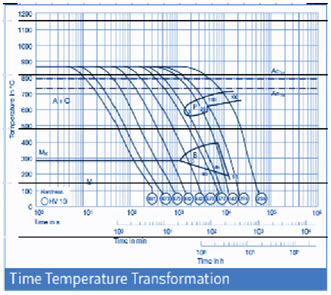

HEAT TREATMENT

| Soft Annealing °C | 710-740 |

| Cooling | Furnace |

| Hardness HB | max. 235 |

| Hardening °C | 850-880 |

| Quenching | Oil or Salt Bath 180-220 °C |

| Hardness after quenching HRC | 51 |

| Tempering°C after quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 52 | 50.5 | 48.5 | 46 | 42 | 36.5 | 28 |

STOCKING PARTNERS

We keep the materials from China and Europe.