DIN 1.2379 / D2 Steel / AISI D2 Tool Steel

| STANDARDS | X153CrMoV12 | HCHCR-D2 | DIN 2379 | AISI D2 | AFNOR Z160CDV12 | JIS SKD10 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Mo | V |

| 1.40-1.60 | 0.10-0.60 | 0.20-0.60 | 0.030max | 0.030max | 11.00-13.00 | 0.70-1.00 | 0.80-1.20 |

Ventura Alloy and Steels Supplies and Stocks HCHCR D2 steel in India and abroad. D2 steel is an air hardening, high-carbon, high-chromium tool steel. It has high wear and abrasion resistant properties. It is heat treatable and will offer a hardness in the range 55-62 HRC, and is machinable in the annealed condition. It tends to be used as threading rolls and dies, icy trimming, cutting & stamping tools for sheet thickness up to 6mm, accuracy cutting instruments for sheet thicknesses up to 12 mm.

STEEL PROPERTIES

- High Carbon High Chromium contents.

- High wear resistant and toughness due to Vanadium addition of 0.90%.

- Supply condition is an Annealed which offer hardness to reach 57-59 HRC.

- Machinable in annealed condition.

- Better than D3 steel due to high alloy properties.

APPLICATION

HCHCR D2 cold work tool steel can be utilized for cold stamping or forming dies, cold forming rolls, slitters, shear blades, tools, chipper knives, tyre shredders, punches, trimming, cutting threading dies, stamping tools and more.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 10.6 |

| 20-200 | 11.5 |

| 20-300 | 11.8 |

| 20-400 | 12.3 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 16.7 |

| 350 | 20.5 |

| 700 | 24.2 |

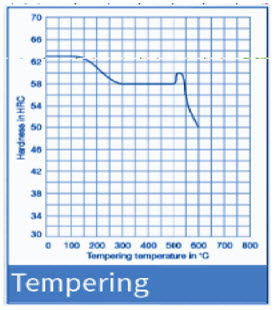

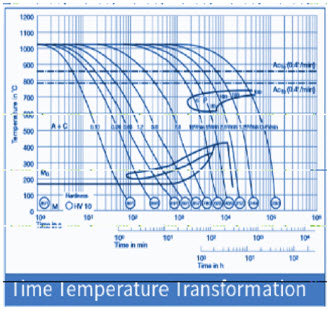

HEAT TREATMENT

| Soft Annealing °C | 840-870 |

| Cooling | Furnace |

| Hardness HB | max. 250 |

| Stress-relief Annealing °C | approx. 660-710 |

| Hardening °C | 1000-1050 |

| Quenching | Air, Oil, Salt Bath 500-550°C |

| Hardness after quenching HRC | 63 |

| Tempering°C after quenching | 100 | 200 | 300 | 400 | 500 | 525 | 550 | 600 |

| HRC | 64 | 61.5 | 58.5 | 58.5 | 59 | 60 | 57 | 50 |

SIZE RANGE

ROUND – 20 to 450 MM | SQUARE – 50 to 155 MM

FLATS – THICKNESS : 20 TO 150 MM | WIDTH : 40 to 450 MM

STOCKING PARTNERS

We keep the materials from China.