A2 / AISI A2 / DIN – 1. 2363

| STANDARDS | X100CrMoV5 | A2 | DIN 2363 | AISI A2 | AFNOR Z100CDV5 | JIS SKD12 | BS 4659 BA2 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.95-1.05 | 0.10-0.40 | 0.40-0.80 | 0.030max | 0.030max | 4.80-5.50 | 0.90-1.20 | 0.15-0.35 |

Ventura Alloy and Steels supplies & stocks A2 Steel in India and abroad. A2 Steel has greater dimensional stability during heat treatment and high wear resistance and strength (potency). It is primarily utilized in cutting instruments, shear razor sharp edges, rolls, cold pilger mandrels, cold stamping devices, moulds for plastics handling.

STEEL PROPERTIES

A2 Steel is equivalent of DIN 2363 and it provides extreme hardness after heat treatment with great dimensional stability. It is heat treatable and offers hardness in the range of 53-63 HRC.

APPLICATION

A2 Steel is mainly used for cutting tools, shear blades, rolls, cold mandrels, moulds for plastics processing, cold stamping tools, blanking tools, trim dies, punch dies, forming dies, stamping dies etc.

PHYSICAL PROPERTIES

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 15.9 |

| 350 | 26.8 |

| 700 | 29.2 |

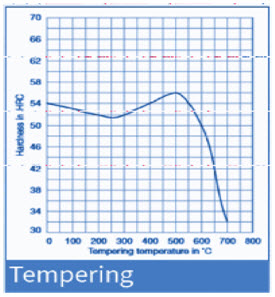

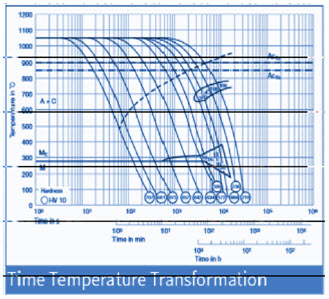

HEAT TREATMENT

| Soft Annealing °C | 810-850 |

| Cooling | Furnace |

| Hardness HB | max. 232 |

| Stress-relief Annealing °C | approx. 650 |

| Hardening °C | 930-970 |

| Quenching | Air, Oil, Salt Bath 500-550°C |

| Hardness after quenching HRC | 63 |

| Tempering°C after quenching | 100 | 200 | 300 | 400 | 500 | 600 |

| HRC | 64 | 63 | 60 | 58 | 59 | 53 |