P20+Ni / AISI P20+Ni / DIN 2738 Plastic Mould Steel

- P20+Ni Plastic Mould

- P20+Ni

| STANDARDS | P20+Ni | DIN 2738 | 40CrMnNiMo8-6-4 | AISI P20+Ni |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Ni | Mo |

| 0.35-0.45 | 0.20-0.40 | 1.30-1.60 | 0.030max | 0.030max | 1.80-2.10 | 1.90-1.20 | 0.15-0.35 |

It has excellent hardening penetration and is specially used for plastic injection die moulds. The characteristics of a material are right sharpening, photo-etching properties with high purity and good homogeneity. P20+Ni is an upgraded version of 2311 plastic mould steel, which is normally supplied in pre-hardened condition. Hardness in as provided condition 280-320 HB with having uniform hardness and the extra nickel content of 1% increases through hardening. It has great machinability, appropriate for plastic molds for medium and huge size, texturing, adequate corrosion resistance, fine polish ability, vacuum-degassed steel. It can be subject to a nitriding treatment to enhance its wear resistance.

STEEL PROPERTIES

- P20+Ni is an upgraded version of 2311 plastic mould steel, which is normally supplied in pre-hardened condition

- Hardness in as provided condition 280-320 HB

- Additional nickel content of 1% increases through hardening

- P20+Ni can be micro-alloyed

- Good machinability

- Suitable for texturing

- Outstanding Polish ability

- Corrosion resistance

- Vacuum-degassed steel with the following excellent features.

APPLICATION

P20+Ni is an equivalent grade of most popular steel grade of DIN 2738 which is applicable for large & small plastic mould dies. It is utilized for automotive industries, bolster plates for presses, dies for domestic goods, die holders and shoe blocks for drop hammers, high finishing plastic die, forging dies, press cassettes, up setter blocker, different dies and mould for plastic products etc.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 11.2 |

| 20-200 | 12.8 |

| 20-300 | 13.5 |

| 20-400 | 13.7 |

| 20-500 | 14.3 |

| 20-600 | 14.7 |

| 20-700 | 14.9 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 35 |

| 350 | 34 |

| 700 | 33 |

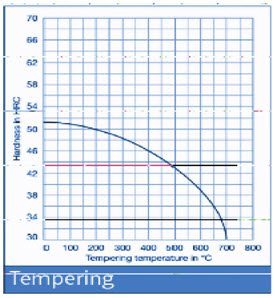

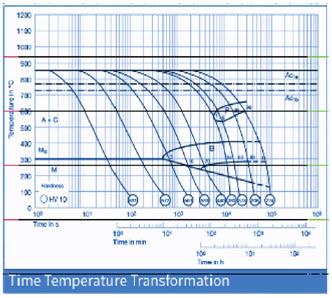

HEAT TREATMENT

| Soft Annealing °C | 710-740 |

| Cooling | Furnace |

| Hardness HB | max. 235 |

| Hardening °C | 840-870 |

| Quenching | Polymer or Oil |

| Hardness after quenching HRC | 51 |

| Tempering°C after quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 51.5 | 50.2 | 48 | 46.2 | 43 | 39 | 29 |

Stocking Partners- We keep the materials from China and Europe.