H11/AISI H 11/DIN 2343

| STANDARDS | X37CrMoV5 | H11 | DIN 2343 | AISI H11 | AFNOR Z38CDV5 | JIS SKD6 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.33-0.41 | 0.80-1.00 | 0.25-0.50 | 0.003 max | 0.030max | 4.80-5.50 | 1.10-1.50 | 0.30-0.50 |

| USA | Europe | Germany | China | Japan | India | R. of Korea | Russia |

| AISI / SAE | En | DIN, WNr | GB | JIS | IS | KS | GOST |

| H11 | X37CrMoV5-1 | X38CrMoV5-1 | 4Cr5MoSiV | SKD6 | XT35Cr5Mo1V3 | STD 6 | 4Ch5MFS |

Ventura Alloy and Steels Supplies and Stocks AISI H11 tool steel is a 5% chromium hot work tool steel that is represented by its excellent impact toughness. Chromium hot-work tool steels are designated as group H steels according to the AISI classification system, and specified in ASTM A681 standard. The most commonly used chromium hot-work steels are H11 tool steel, H12 tool steel, and H13 steel, within the series from H1 to H19.

If we compare between H11 and H13, H11 tool steel consists of less vanadium than the commonly used H13 hot work tool steel. This gives H11 steels the higher toughness, with some reduction in wear resistance and tamper resistance. H11 tool steel is a deep-hardening, air-hardening steel and H11 alloy steel could be deep hardened by heat treatment and air-quenching. That gives minimal size change during heat treatment. H11 how work steel also has super resistance to thermal fatigue cracking and superb resistance to gross cracking and thermal shock when water cooled in service.

H11 steel is inclusive of all hot work tool steel with excellent rigidity and durability along with great thermal conductivity and invulnerability to hot cracking and can be water cooled to a constrained degree. H11 is primarily used for apparatus holders , ejector pins and shrink fit chucks.

STEEL PROPERTIES

- Contains 5% Chromium

- Greater strength

- High toughness

- Best thermal physical phenomenon

- Resistant to hot cracking

- Gives fundamental necessities to long tool life in press forging, die-casting, extrusion processes etc.

APPLICATION

This grade isn’t utilized for typical applications in the area of hot-work steels, yet additionally useful for tool holders, bridge kind tools, ejector pins, liner holders, hot work punches, forging dies, and shrink work chucks.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 11.7 |

| 20-200 | 12.3 |

| 20-300 | 12.5 |

| 20-400 | 12.7 |

| 20-500 | 12.75 |

| 20-600 | 12.9 |

| 20-700 | 12.9 |

| Thermal Conductivity at °C | W / (m*K) Annealed | W / (m*K) Quenched & Tempered |

| 20 | 29.8 | 26.5 |

| 350 | 30.0 | 27.4 |

| 700 | 35.5 | 30.4 |

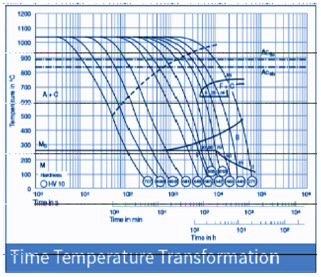

HEAT TREATMENT

| Soft Annealing °C | 750-800 |

| Cooling | Furnace |

| Hardness HB | max. 230 |

| Stress-Relief Annealing °C | approx. 600-650 |

| Hardening °C | 1000-1030 |

| Quenching | Air, Oil, Salt Bath 500-550°C |

| Hardness after quenching HRC | 54 |

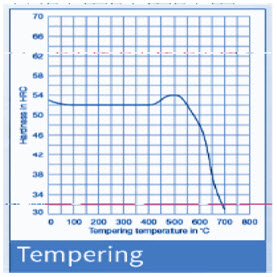

| Tempering°C after quenching | 100 | 210 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 52 | 52 | 52 | 52 | 54 | 53 | 48 | 37 | 31 |

SIZE RANGE

ROUNDS – 71 to 300 MM DIA

FLATS -Thickness – 20 to 400 MM MAX | Width – 40 to 700 MM MAX

STOCKING PARTNERS

We keep the materials from China.