H12 / AISI H12 / DIN 1.2606

| STANDARDS | X37CrMoW5-1 | H12 | DIN 2606 | AISI H12 | AFNOR 32CDV12-28 | JIS SKD62 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | W | Mo | V |

| 0.30-0.40 | 0.80-1.25 | 0.20-0.60 | 0.003 max | 0.030max | 4.75-5.50 | 1.00-1.70 | 1.25-1.75 | 0.20-0.50 |

| USA | Germany | Japan | British |

| AISI / SAE | DIN, WNr | JIS G4404 | BS 4659 |

| H12 / T20812 | 1.2605 / X35CrWMoV5 | SKD62 | BH12 |

H12 Hot Work Die Steel could be a five-hitter Cr, general hot work steel that is characterized by wonderful effect strength. It contains less vanadium than the broadly utilized H13 hot work tool steel, and furthermore the tungsten content gives higher temper resistance. It has smart resistance to thermal fatigue cracking (heat checking) and excellent resistance to gross cracking and thermal shock once water cooled in commission. TLS H12 hot work tool steel is normally prescribed for warm tooling applications wherever most resistance from cracking is required. Such applications grasp die casting, hot punches, hot shear cutting edges, shaping dies, extrusion tooling and hot gripper dies.

STEEL PROPERTIES

- Magnificent Resistance to Wear

- High Strength at Elevated Temperature

- Homogenizing with High Toughness

- Additional Fine Structure without Grain-Boundary Carbide

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 11.7 |

| 20-250 | 12.4 |

| 20-500 | 12.9 |

HEAT TREATMENT

| Soft Annealing °C | 820 |

| Cooling | Furnace |

| Hardness HB | max. 240 |

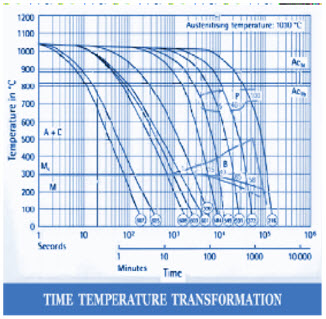

| Hardening °C | 1030-1130 |

| Quenching | Oil or Hot Bath 500-550°C |

| Hardness after quenching HRC | 57 |

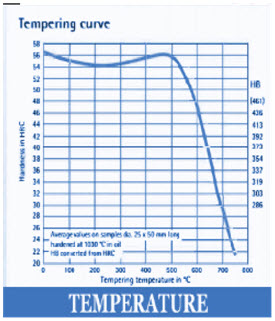

| Tempering°C after quenching | 100 | 210 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| HRC | 55 | 54 | 54.3 | 54.8 | 53 | 51 | 48 | 41 | 34 |