H10 / AISI H10 / DIN 1.2365 / SKD7

| STANDARDS | X210CrW12 | H10 | DIN 2365 | AISI H10 | AFNOR 32CDV12-28 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | Mo | V |

| 0.28-0.35 | 0.10-0.400000 | 0.20-0.40 | 0.003 max | 0.030max | 2.70-3.20 | 2.50-3.00 | 0.40-0.75 |

| USA | Germany | Japan | British |

| AISI / SAE | DIN, WNr | JIS G4404 | BS 4659 |

| H10 / T20810 | 1.2365 / 32CrMoV12-28 | SKD7 | BH10 |

Ventura Alloy and Steels Supplies & Stocks H10 Steel in India and abroad. H10 is an amazing high-temperature quality and treating resistance, thermal conductivity and low powerlessness to hot cracking. It can be water cooled to a restricted degree and also suitable for cold hobbling. Utilized for press and penetrating mandrels pass on supplements, massive metal die casting tools.

STEEL PROPERTIES

- Hot Work Steel H10 is equivalent steel of DIN 2365

- Great tempering resistance

- Less susceptible for high hot cracking

- Excellent thermal conductivity

- High-temperature durability

- Can be water-cooled to a constrained degree

APPLICATION

This tool steel is used for hot press and mandrels, press die inserts and forging die, remarkable hot metal die casting tools, die-casting moulds for non-ferrous overwhelming metal pressure die-casting.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 11.7 |

| 20-200 | 12.4 |

| 20-300 | 12.7 |

| 20-400 | 13.2 |

| 20-500 | 13.5 |

| 20-600 | 13.7 |

| 20-700 | 13.8 |

| Thermal Conductivity at °C | W / (m*K) |

| 20 | 32.6 |

| 350 | 34.4 |

| 700 | 32.4 |

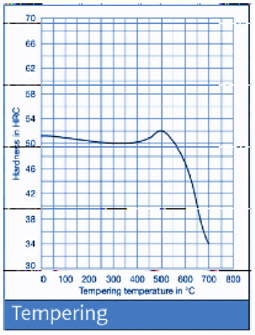

HEAT TREATMENT

| Soft Annealing °C | 740-800 |

| Cooling | Furnace |

| Hardness HB | max. 185 |

| Hardening °C | 1040-1060 |

| Quenching | Oil or Hot Bath 500-550°C |

| Hardness after quenching HRC | 52 |

| Tempering°C after quenching | 100 | 210 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 51 | 50.5 | 50 | 50 | 53 | 51 | 48 | 41 | 34 |