H21 / AISI H21 / DIN 1.2581

| STANDARDS | X30WCrV-3 | H21 | DIN 2581 | AISI H21 | AFNOR 32CDV12-28 | JIS SKD5 |

CHEMICAL COMPOSITION (Typical Analysis in %)

| C | Si | Mn | P | S | Cr | W | V |

| 0.26-0.36 | 0.15-0.25 | 0.20-0.40 | 0.003 max | 0.030max | 3.00-3.75 | 8.50-10.00 | 0.30-0.60 |

| USA | France | Germany | China | Japan | England | Sweden |

| AISI / SAE | AFNOR | DIN, WNr | GB | JIS | BS | SS |

| H21 / T20821 | X30WCrV9 | X30WCrV93 / 1.2581 | 3Cr2W8V | SKD5 | BH21 | 2730 |

H21 Steel is a hot work tool steel for oil or air hardening to develop high hot quality, support of hardness, and warmth checking resistance.

This is mostly utilized as hot work devices, instruments for manufacture of hollows, screws, rivets, nuts and bolts. Die casting tools, forming dies, die inserts, hot shear blades.

STEEL PROPERTIES

Hot work steel has great toughness and contains Tungsten, Chromium, Carbon, Vanadium and generally its working hardness is 40.0 to 55.0 HRC size and is accessible in round, level and square shapes.

APPLICATION

The H21 tungsten hot-work tool steels are primarily utilized for hot-working dies and tooling. For example extrusion, die casting & hot-forming of parts.

PHYSICAL PROPERTIES

| Coefficient of Thermal Expansion at °C | 10¯⁶ m / (m*K) |

| 20-100 | 11.2 |

| 20-200 | 11.9 |

| 20-300 | 12.2 |

| 20-400 | 12.5 |

| 20-500 | 12.8 |

| 20-600 | 13.0 |

| 20-700 | 13.2 |

| Thermal Conductivity at °C | W / (m*K) |

| 100 | 27.0 |

| 400 | 29.8 |

| 675 | 29.1 |

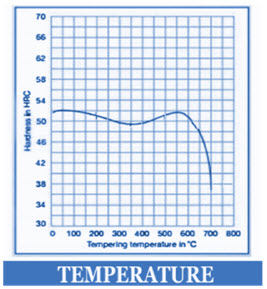

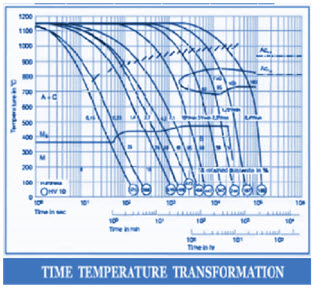

HEAT TREATMENT

| Soft Annealing °C | 780-810 |

| Cooling | Slowly |

| Hardness HB | max. 240 |

| Hardening °C | 1000-1130 |

| Quenching | Oil or Hot Bath 600-650°C |

| Hardness after quenching HRC | 53 |

| Tempering°C after quenching | 100 | 210 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 49 | 49 | 49 | 49 | 51 | 51 | 50 | 46 | 36 |